Injection molding has become a popular manufacturing method for producing plastic products. It provides cost-effective production processes suitable for a variety of industries. When it comes to injection molding, selecting the right machine is critical to achieving the desired quality, efficiency and productivity.

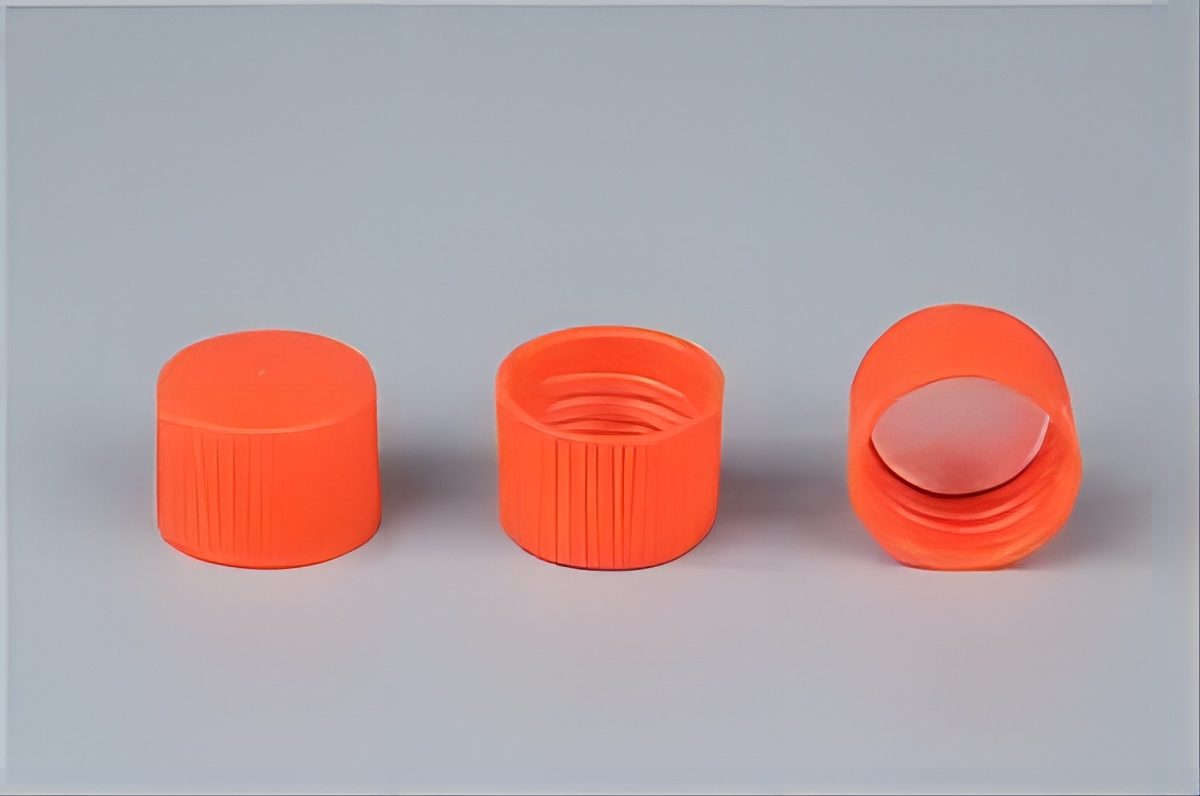

Mingsanfeng Cap Mould Co., Ltd. is a company specializing in the development, production, sales and service of plastic bottle cap injection molding. With their expertise in the field, they provide valuable insight into choosing the right injection molding machine for cap molds and injection screw caps.

Choosing the right machine depends on many factors, including the type of plastic to be molded, the shape and dimensional accuracy of the product, the quality of appearance, and the requirements of use. In addition, production batch size, material properties such as cutting, polishing, welding, etching, deformation and wear resistance, as well as economic considerations, mold manufacturing conditions and processing methods all play an important role in the decision-making process.

When it comes to cap molds and injection molded screw caps, it is crucial to consider the specific requirements of the final product. The mold should be able to produce a cap that meets the required specifications, such as size, shape and tightness of the seal. Additionally, the injection molding machine should be able to provide consistent and precise control over the injection process to ensure uniformity and accuracy of each cap produced.

As far as the injection molding machine itself is concerned, there are various types such as hydraulic machines, electric motors, and hybrid machines. Each type has its advantages and disadvantages. For example, hydraulic presses offer high injection power and versatility, making them suitable for a variety of applications. Motors, on the other hand, offer energy efficiency and faster response times. Hybrid machines combine the advantages of hydraulic machines and electric motors.

When choosing an injection molding machine, it is also critical to consider throughput. If producing large batches, a high-speed machine with a large number of cavities may be ideal for high production rates. However, for smaller volumes or special requirements, a machine with lower capacity but higher flexibility may be more suitable.

In conclusion, choosing the right injection molding machine is crucial to the successful production of bottle cap molds and injection screw caps. Taking into account factors such as plastic type, product specification, output and economic considerations, choosing the right machine can ensure optimum efficiency, productivity and quality. Mingsanfeng Cap Mould Co., Ltd. provides expertise in this field, providing valuable insights and solutions for injection molding needs.

Post time: Jul-03-2023